Coating of Membranes & Polymer Fabrics

Polymer fabrics and membranes are important for a plethora of engineering and functional applications, including, but not limited to, filtration, tissue engineering, implants (polymer fabrics) and water harvesting. However, surface modification is often needed in order to fully take advantage of their potentials. Examples include the hydrophilic modification of membranes for Oil-water separation, biomimetic hydrophilic-hydrophobic structuring of fabrics for water harvesting (from fog, humid air) and hydrophilic/antibiofouling modification of implant fabrics, e.g. for the minimal invasive surgery treatment of hernia.

At IMST two coating procedures and chemistries were developed for the surface modification of polymer fabrics and membranes:

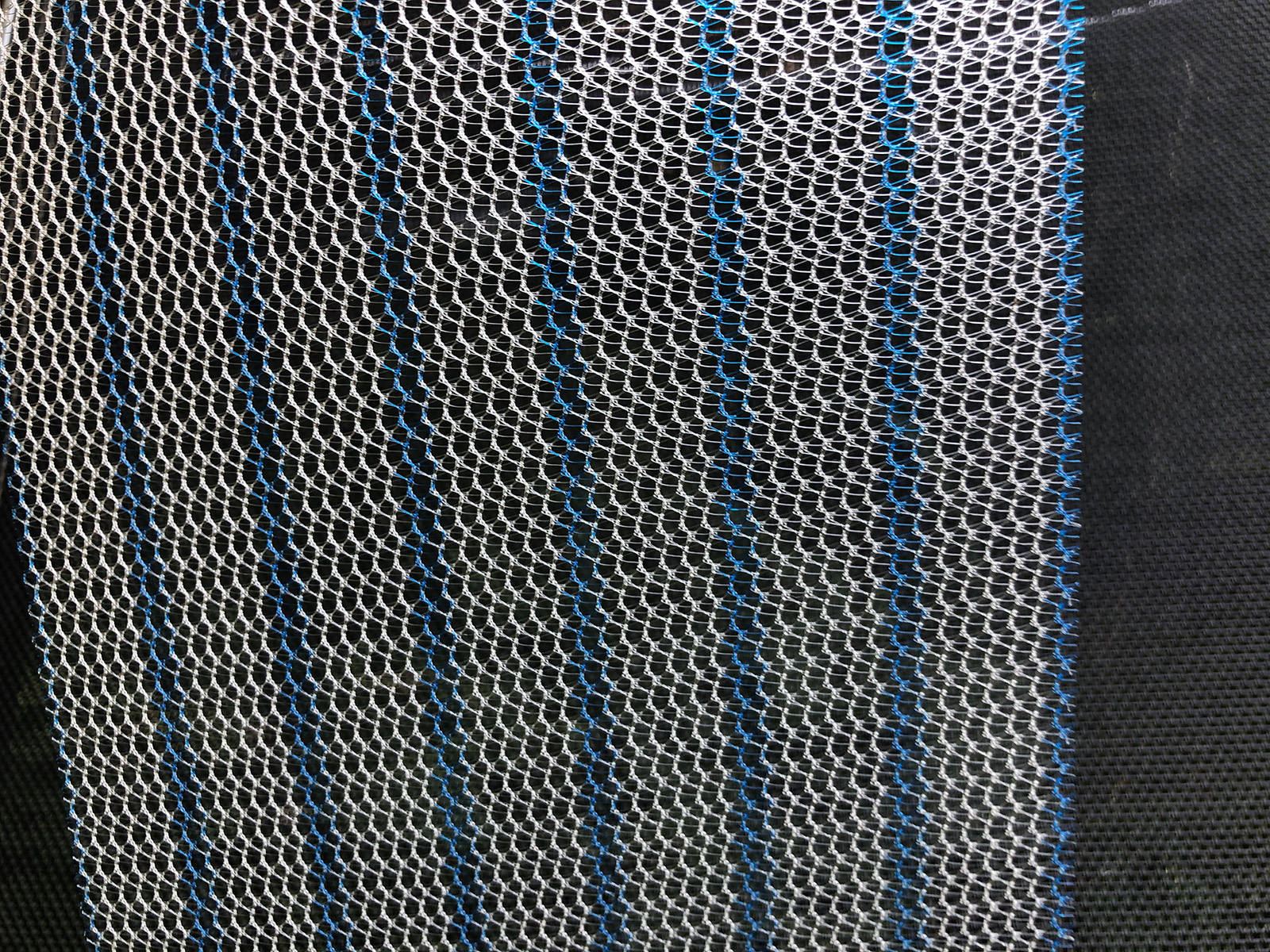

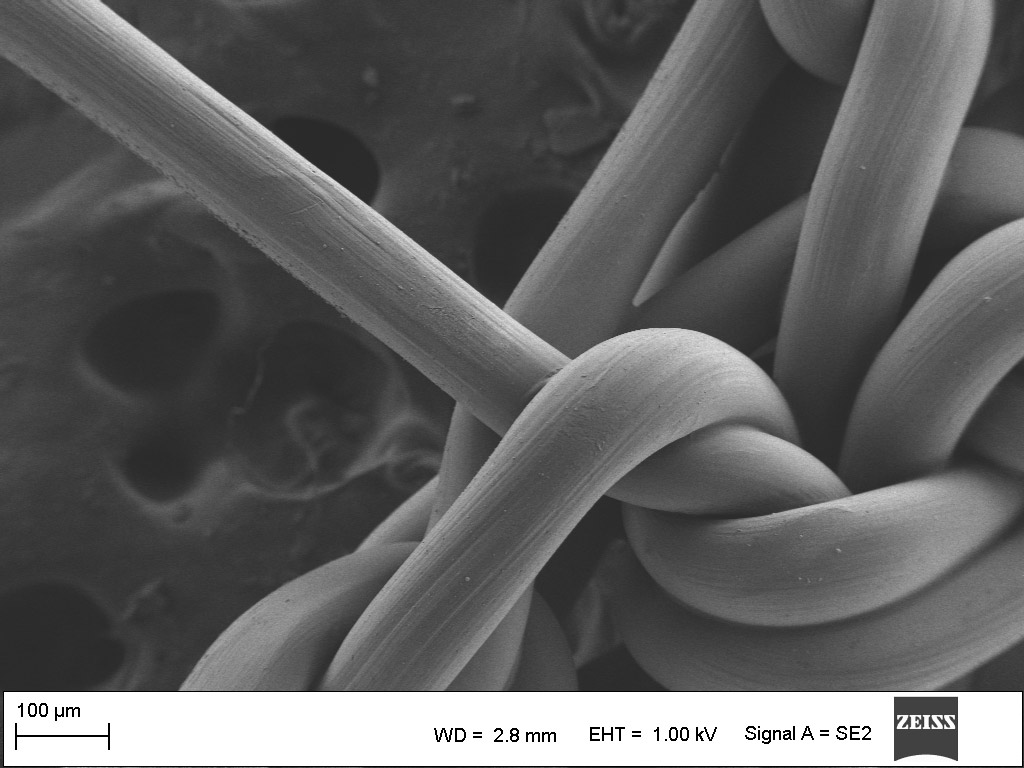

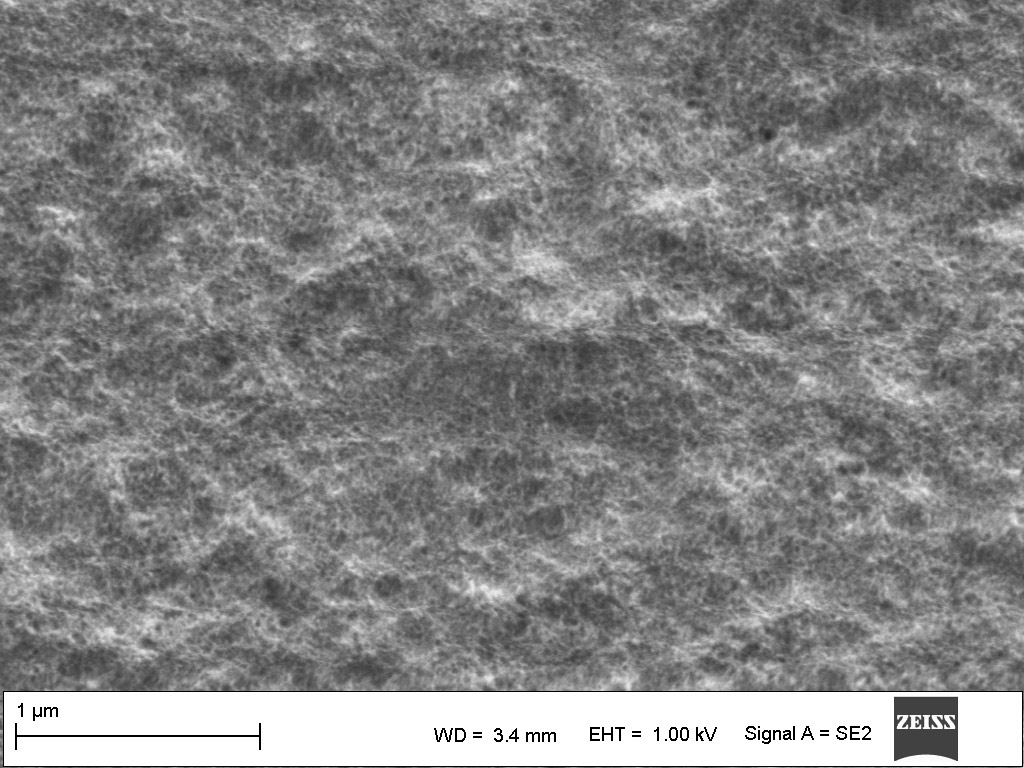

- The first one relies on metal oxide nanoscales, including silicon, titanium and zinc oxides that are directly deposited on the surface using a sol-gel method from aqueous solutions (Coating for Polymers, European Patent Nr. 12 732 952.2). the following photographs/micrographs depict a polypropylene fabric with a zinc oxide nanoscale at different magnifications. The high-resolution scanning electron microscope (SEM) image (lower right image) shows the fine morphology and the homogeneous character of the film on one thread.

Photographs and micrographs of a zin oxide modified polypropylene fabric at different magnifications. The lower right SEM image depicts the morphology of the nanoscale coating.

2. The second procedure relies on the photografting of superhydrophilic, zwitterionic polymer films, similarly to what is described for Polymers & Silcones.

A sequential coating consisting of an oxide scale and a polymer overlayer on polymer fabrics and membranes can als o be realized easily.